| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : JIN MACHINE

Model Number : JIN-75

Certification : CE Certificate

Place of Origin : CHINA

MOQ : 1 Set

Price : Negotiable

Payment Terms : T/T, L/C, D/A, D/P, Western Union, MoneyGram

Supply Ability : 10 sets per month

Delivery Time : 45 work days

Packaging Details : Standard wooden frame and wooden case is available for Jin Machine Excellent Rigid Packaging drying dryer for plastic recycling

Application : PET granulating

Material : 304 Stainless Steel

Raw Material : PET Flakes or bottles

Motor : Siemens Brand

Warranty : 12 Months

Production Period : 55 Days

Capacity : 250 kg/h

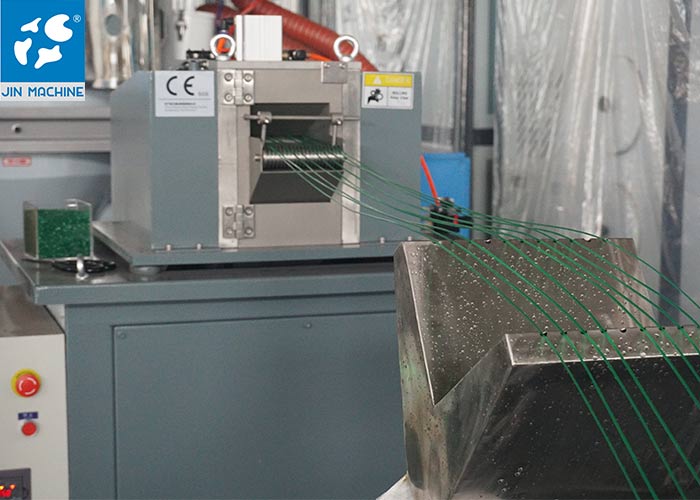

250KG/H Plastic Granules Making Machine For Recycling Extruder/Pelletizer

1. Introduction of JIN MACHINE

We are Jin Machine, we are a modern family-owned enterprise. Which contains two mechanical manufacturing companies. Jinguan and Jinyue. Jinguan was established in 2006, focusing on mechanical design; Jinyue was established in 2017, focusing on research and development of drying and central conveying. Through 13 years of experience and technical accumulation, Jin Machine now offers a single machine or a complete set of centralized feeding, compounding, recycling and drying systems. We have excellent mechanical control, ultra-low energy consumption which is comparable to imported equipment. Besides, our fast after-sales response can let our customers get asuperb service experience.

2. Product Parameters

| Equipment Model | JIN-75A |

| Screw Diameter(mm) | 71 |

| Screw Length To Diameter Ratio | 28-60 |

| Screw Speed(r/min) | 500/600 |

| Main Motor Power(KW) | 90/110/132 |

| Screw Torque(N.m) | 1210 |

3. Product Description of pelletizer

4. Security Protection:

A. coupling can effectively protect the reduction gearbox from extrusion unit overload dangers.

B. water-cooling system and lubrication systems are all real-time online monitoring.

5. Material Process

A. water-cooling strands pelletizer:

1. high-sped mixer 2. solids-conveyer 3. main feeder 4. side feeder 5. side feeder 6. twin-screw extruder 7. water trough 8. air-knife 9. pelletizer 10. product container

Application:

1.Fiber reinforcement: glass fiber, carbon fiber reinforced PP,PA,PBT,ABS,AS,PC,POM,PPS,PET,PPO,PSF,LCP,etc.

2.Ploymer blending :bleding of PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+SBS,etc.

3.Incorporation of fillers :CaCO3,Tale,TiO2,carbon black filled PE,PP,or EVA etc.

4.Cable Compounds:cable sheath,cable insulation compounds of LDPE,HDPE,LLDPE,MDPE;radiation-crosslinkable compounds ,optical fiber protection compounds ,heat-shrinkable polymer compounds.

5.Special Compounds :PPR pipe compounds,PE compounds for crosslinked pipes,tobacco filter

compounds,etc

6.High Concentration Color Masterbatches: PE,ABS,PS,EVA,PET,PP etc. With high concentration of pigments and other procrssing aids.

7.Masterbatches with Flame Retardants:PP,PA,ABS,EVA,PBT etc.with flame retardants and other

additives.

B. Air-cooling hot-face pelletizer

Application :

Enforcing modification PE,EVA etc.+CaCO3 ,talc,TiO2,carbon black.

Degradable master batch:PE,PS etc. + starch,additive etc.

Anti-flame master batch :PE,EVA etc. +Sb2O3,Mg(OH)3 etc.

C. water-ring hot-face pelletizer

1. high-speed mixer 2. main feeder 3. side feeder 4. twin-screw extruder

5. water ring granulator 6. centrifugal off-water machinery 7. vibrating sieve

8. product container

Application:

1.PE,EVA etc. ,filled with CaCO3,talc,TiO2,carbon black etc.

2.Cable sheath , cable insulation compounds of LDPE,HDPE,LLDPE,or MDPE;

3.TPR,TPU TPV thermoplastic elastomers; EVA and hot-melt adhesives

4. Flame retardant masterbatcher of ABS,EVA etc;

6. Why choose JIn Machine

With more than decades of practical experience, JIN MACHINE Co., Ltd. has been in the field of manufacturing extrusion machine. We strive to maintain the quality and customer satisfaction as they are our business objective.

Some of most considerable factors of JIN MACHINE Co., Ltd.Ethical business policies

|

|

250KG/H Plastic Granules Making Machine Images |